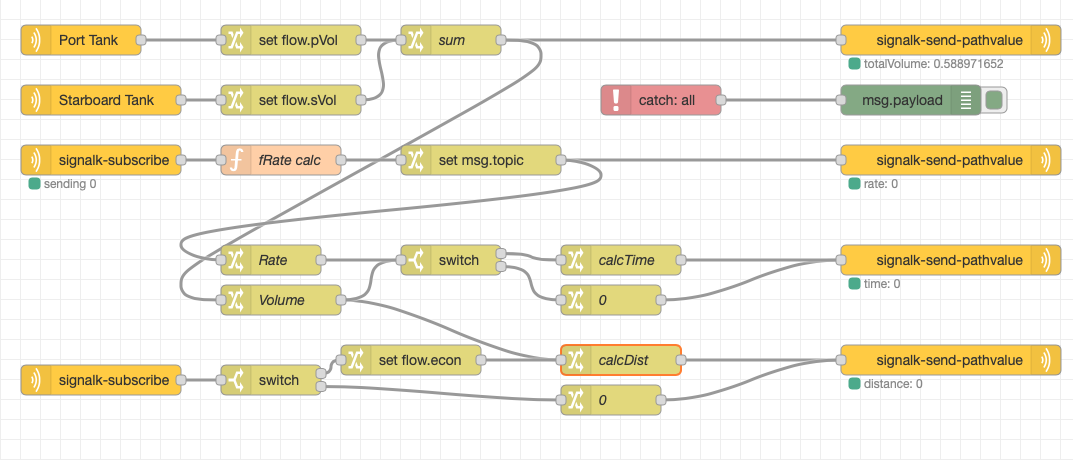

Derived data is by far my favorite plugin. I just installed an AlbaCombi analog-to-digital interface for the old Lehman diesel and am now using MOST of the data calculated Derived Data. There was some stuff missing, however, as I have multiple tanks and the "economy" feature of the plugin doesn't calculate estimated distance or estimated running time. So I struggled through a node red flow to calculate some extra fields. See screen shot.

The first flow brings in the volume of port and starboard tanks, adds them together, and sends out a "total volume" path to SK.

The third line down brings in the engine RPMs and then calculates the fuel flow rate, based on a formula I calculated from a graph of the data for my engine I plotted in Excel. This is not the "actual" flow rate, but are based on manufacturers information. The graph formula wasn't 100% accurate to the curve of the data, so I used Scott Benders "Calibration" plugin to further fine tune those numbers to exactly match the manufactures specs. Again, not actual fuel rate, but close enough for my needs. Fuel Rate is sent back out to SK as Derived Data uses it to calculate fuel economy.

Those two pieces of data are used to further calculate range time and distance, so I have estimates of how long I can run my engine and how far I can go based on fuel volume and fuel economy.

These flows were sending back a bunch of errors as there were a few "NaN"s and a few places where the formulas would try to divid by "0" if the engine wasn't running, so I adjusted to minimize those errors and ease the error handling load on SK server.

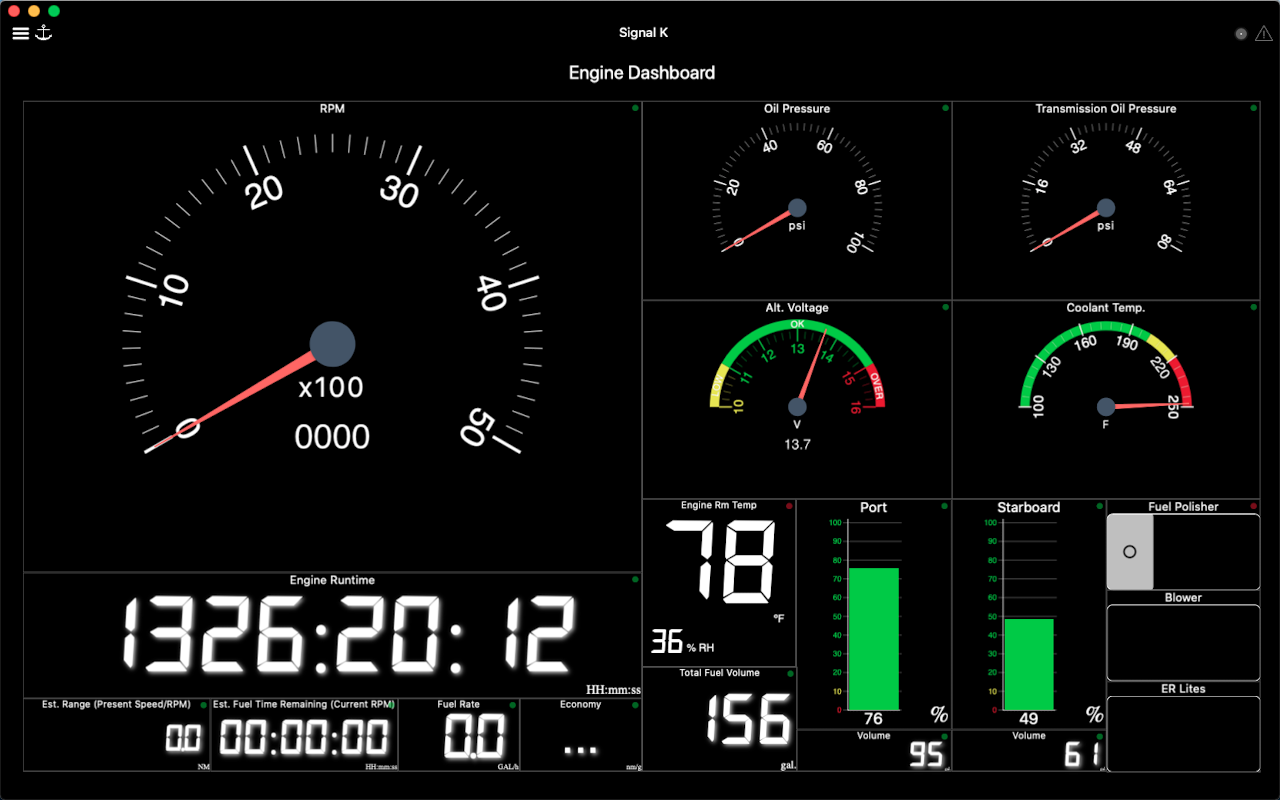

Here's my engine pane with the extra fields in place. Engine is not running, so most of them are zeros.

The first flow brings in the volume of port and starboard tanks, adds them together, and sends out a "total volume" path to SK.

The third line down brings in the engine RPMs and then calculates the fuel flow rate, based on a formula I calculated from a graph of the data for my engine I plotted in Excel. This is not the "actual" flow rate, but are based on manufacturers information. The graph formula wasn't 100% accurate to the curve of the data, so I used Scott Benders "Calibration" plugin to further fine tune those numbers to exactly match the manufactures specs. Again, not actual fuel rate, but close enough for my needs. Fuel Rate is sent back out to SK as Derived Data uses it to calculate fuel economy.

Those two pieces of data are used to further calculate range time and distance, so I have estimates of how long I can run my engine and how far I can go based on fuel volume and fuel economy.

These flows were sending back a bunch of errors as there were a few "NaN"s and a few places where the formulas would try to divid by "0" if the engine wasn't running, so I adjusted to minimize those errors and ease the error handling load on SK server.

Here's my engine pane with the extra fields in place. Engine is not running, so most of them are zeros.